Manufacturing Equipment

We pride ourselves on impeccable quality, achieved through rigorous testing and a sufficient production line capable of manufacturing a wide range of products.

Quality Control

PROCESS CHECK SHEET

-

Scrap Nonwoven

-

Mark checks with red tape before nonwoven production

-

Confirm setup with red tape when producing latex-coated nonwoven on the backside

IMPORT INSPECT PROCESS

-

01

MATERIAL IMPORT

Products arrive in 250KG/1 BALE with a LOT standard of 8 tons from the raw material supplier.

-

02

MATERIAL Inspect

Sampling based on 1 LOT = 8 tons to check the COLOR condition in the raw material state.

SEMI-PRODUCT INSPECT PROCESS & FINAL PRODUCT INSPECT PROCESS

-

01

MATERIAL IMPORT

Confirm color sample limits and any color variations before proceeding with work.

-

02

W/PAPER PROCESS

Check the established color samples and operate 3 times per LOT.

-

03

LATEX COAING

Compare the color of the fabric produced after latex coating with the color sample, proceed with work after 3 comparisons per LOT.

-

04

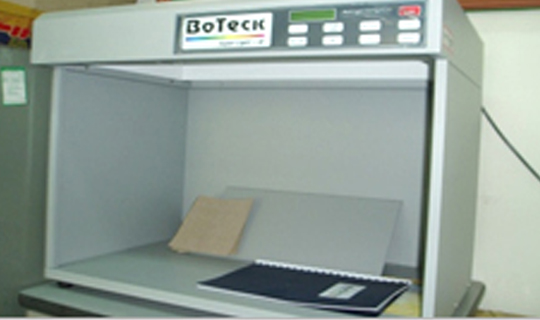

COLOR INSPECT (DAYLIGHT BOX)

Color verification by LOT