Business Sector

We specialize in manufacturing high-functionality

automotive interior materials using eco-friendly textile materials.

Our diverse range of non-woven fabrics are produced under the brand "Felt Korea."

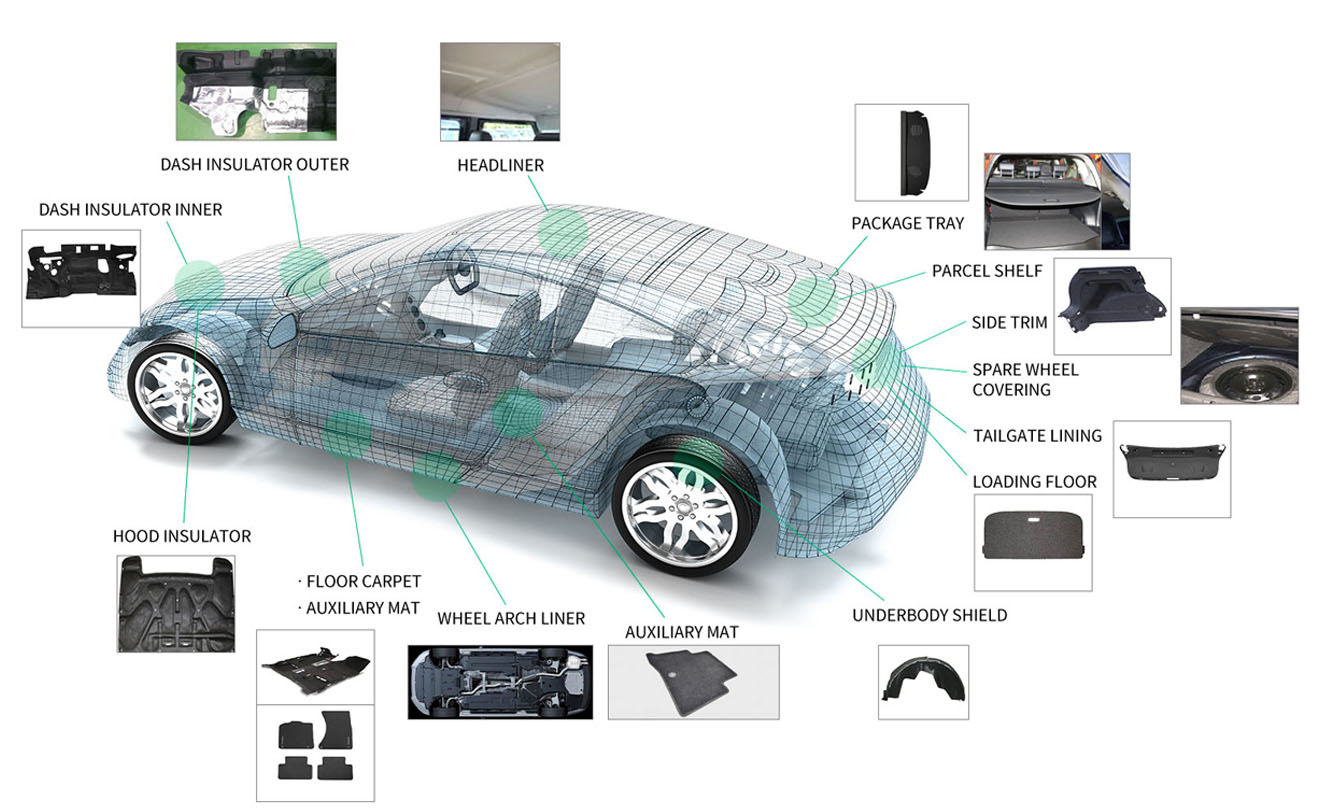

Automotive Interior Materials

Advantages of Wonpung

Elevating Your Vehicle's Elegance with Premium Interior Materials, Bringing Comfort to Your Life.

WONPUNG

AUTOMOTIVE FIELD SERIES

Specialized Manufacturer of Molded Products for Automotive Interiors, Wonpung Mulsan Co., Ltd.

We produce eco-friendly materials capable of mitigating Noise, Vibration, and Harshness (NVH). Our process excludes the use of latex chemicals and instead employs a three-layered structure consisting solely of non-woven fabrics for sound absorption, insulation, and an additional layer for absorption. This approach enables us to maintain an environmentally responsible manufacturing process.

- Automotive sound-absorbing material for UNDER HOOD, interior, trunk, floor, and exterior applications

- Sound-absorbing material for other automotive interior components requiring high elasticity

Features of Wonpung Mulsan's Eco-Friendly Sound-Absorbing Material

- NVH Performance

- Environmentally Friendly Manufacturing Method

- Lightweight

- Robust Durability

- Fire-Resistant Material

- Cost-Efficient

Advantages of Wonpung (Compared to Competitors)

- We have the capability to produce an array of approximately 200 different colors and various patterns.

- Our extensive production lines ensure that we avoid any product shortages. Our facilities include 5 general non-woven lines, 5 high-velour lines, 2 latex coating lines, 2 film coating lines, and 3 automatic cutting lines.

- We are a registered collaborating entity with KATRI (Korea Apparel Testing & Research Institute), KOTMI (Korea Textile Machinery Research Institute), and KDTI (Korea Textile Development Institute), which enables seamless feedback on various tests and data.

- Currently, we supply to HMC/KMC/GM/SsangYong Motor/Renault Samsung, which allows us to adapt to various specifications. All types of tests are performed under a recognized contract with KATRI, demonstrating our extensive experience in this area. We possess the ability to test according to the specifications of these four companies (4-company related non-woven spec testing capability).

Production Lines - Comprehensive Supply of Composite Non-Woven Products Available

- General Non-Woven Production Lines: 5 lines available, each with diverse color options. Additionally, 5 needle punching lines are in operation.

- Eudora or Marz Type Lines: 5 lines dedicated to specialized products like floor mats and high-specification non-wovens.

- Drying Lines: 2 lines specifically for treatments such as flame retardancy, water repellency, and foaming.

- Film Coating Lines: 2 lines dedicated to PE film coating.

- Cutting Lines: Separate cutting section in operation with 4 distinct lines.