Research and Development

Continuous challenges and innovations for a new future

Research and Development Direction and Content

Leading the global market through ceaseless research and development in cutting-edge technologies for nonwoven fabric forming companies!

WONPUNG

research and development

We take the lead in developing industrial composite nonwoven fabric products using eco-friendly techniques.

We produce a variety of industrial composite nonwoven fabric products considering sound absorption, lightness, thermal insulation, and shape stability.

Key Research Areas of the Laboratory

- Research on acoustic absorption nonwoven fabric for automotive interiors, superfiber research for automotive exteriors and engines

- Development of film extrusion technology and 3-layer film composite technology

- Technology development for automotive and home textile carpets, complexing technology for water and sewage liners

- Development technology for composite materials for electronic components, heat-blocking and heat-sensing pressure-sensing nonwoven fabric material

- Development of layered noise-dampening materials, research and development related to waterproof sheet composites

- Development and forming technology for recycling materials, development of polyester, pp, lm, elastic fiber, and sheath-core fiber materials

-

Design researsh

Acoustic Absorption Composite Nonwoven Fabric Design Study

-

Design development

Direct film extrusion production and coating extrusion screw, film design development

-

Complexation

Design for the complexation of Pile nonwoven fabric line

-

Design structure

Pipe-compatible composite liner design configuration

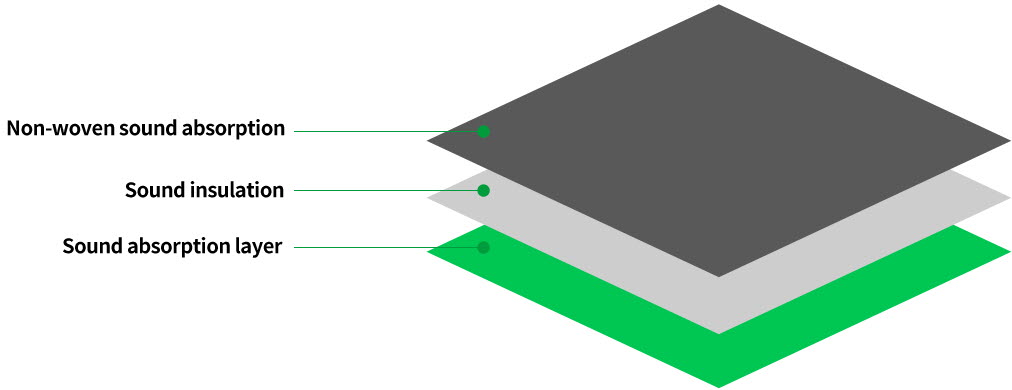

Eco-friendly materials capable of preventing NVH (Noise, Vibration, and Harshness)

Manufactured through an eco-friendly process, eliminating the use of latex chemicals and consisting solely of a 3-layer structure of acoustic absorption + sound insulation + absorption layer

Core Technical Elements

- Development of LOW-MELTING FIBER manufacturing technology without using flame retardants

- Development of IMPREGNATION PROCESS for enhanced wear resistance

- Development of nonwoven fabric manufacturing technology with superior PILE strength

- Technology development for improved impregnation by LOW MELTING methods as an alternative to using ACRYLIC LATEX for back coating